During the busiest harvest season each year, the baler, as an essential part of agricultural machinery, also bears immense workload pressure. While its operational pace may not be as urgent as that of the harvester, its efficient and stable performance is equally critical to the overall productivity of the farm.

For farmers, the baler needs to work efficiently while withstanding heavy loads and frequent vibrations. For engineers, every core component of the baler must work in precise coordination to ensure smooth operation of the mechanical system and minimize the risk of downtime due to malfunctions.

Among the massive machinery, there is a crucial yet often overlooked "unsung hero" that directly affects both efficiency and lifespan — the mounted bearing in the guide roller system. While it does not directly participate in the baling process, it endures continuous shocks, fluctuating torque loads, and the challenges of mud, water, and dust. If it fails, the guide system could jam or even disconnect, leading to machine downtime and disrupting the entire operation.

To meet the demanding conditions, LDK has deeply focused on the baler’s usage scenario and launched specially designed mounted bearings with four-hole, six-hole, and round-hole configurations for the guide system. Every detail is crafted with performance in mind.

In terms of structural design, LDK products use an eccentric sleeve locking method for easy disassembly and reliable, secure assembly. The four-hole and six-hole designs enhance torque transmission efficiency and reduce the risk of screw loosening, greatly simplifying machine assembly and subsequent maintenance, especially in flexible applications with non-standard shafts or changing shaft conditions.

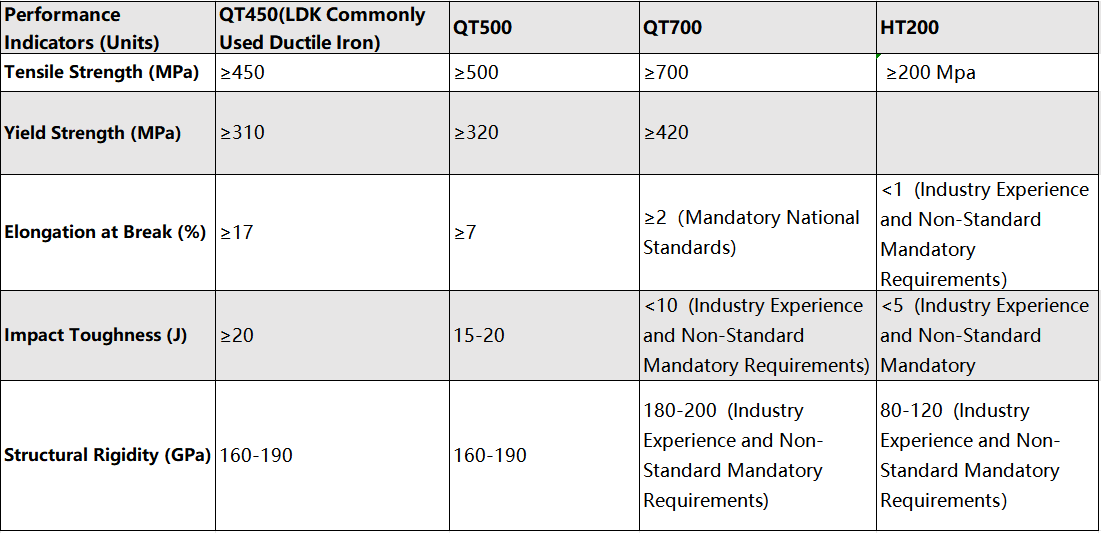

LDK mounted bearings are made of high-strength gray cast iron or ductile cast iron, offering exceptional structural rigidity and impact resistance. Even under frequent vibrations and heavy loads, they maintain structural stability, are resistant to fracture or deformation, and effectively support long-term continuous operation of the equipment.

For equipment manufacturers and farmers, LDK bearings offer significant advantages:

For Equipment Manufacturers:

Flexible design: Compatible with non-standard shafts and complex layouts

Stable structure: Reduces wear, extending the equipment lifecycle

Efficient assembly: Low tolerance requirements, no need for precise alignment

For Agricultural Users:

Easy maintenance: Convenient replacement, reducing repair frequency

Strong adaptability: Impact-resistant and mud-proof, suitable for harsh farming environments

Economical and durable: Long service life, reducing replacement costs

As the baler moves through vast fields during harvest, each stable rotation and precise guidance reflects the immense carrying capacity of LDK bearings. They are not isolated components, but the reliable support that guarantees agricultural efficiency.

In this era that demands high efficiency and reliability, let’s drive the future of agricultural equipment with a more solid foundation.